SmartGen HGM8140Z Genset controller

* All prices on this website are retail in USD on EXW incoterms

Technical Parameters:

Display LCD(132*64)

Operation Panel Silicon Rubber

Language Chinese & English & Spanish

Relay Output 7

AC System 1P2W/2P3W/3P3W/3P4W

Alternator Frequency 50/60Hz

Monitor Interface RS485/ETHERNET

Programmable Interface RS485/USB/EHTERNET

CANBUS(1939) ●

RTC & Event Log ●

Scheduled Start Genset ●

Maintenance ●

Ethernet ●

DC Supply DC(8~35)V

Case Dimensions(mm) 136*110*41

Panel Cutout(mm) 121*93

Operating Temp. (-40~+70)℃

Product Overview:

HGM8140Z genset controller, integrating digital, intelligent and network technology, adopts “Main Control and Display” separated type mode. It is suitable for single unit automation and monitoring system to achieve automatic start/stop, data measurement, alarm protection as well as remote control, remote measurement and remote communication functions. It can work in (-40°C~+70°C) and has LCD display, selectable Chinese, English and Spanish interface, which is reliable and easy to use.

The SAE J1939 port on the controller makes it possible to communicate with a number of ECU (ENGINE CONTROL UNIT) equipped with J1939.

The controller adopts micro-processor technology with precise parameters measuring, fixed value adjustment, timing and threshold setting and etc. Major parameters can be configured from front panel, and all parameters can be configured by USB interface (or RS485, ETHERNET) to adjust via PC. It can be widely used in all types of automatic genset control system with compact structure, advanced circuits, simple connections and high reliability.

PERFORMANCE AND CHARACTERISTICS

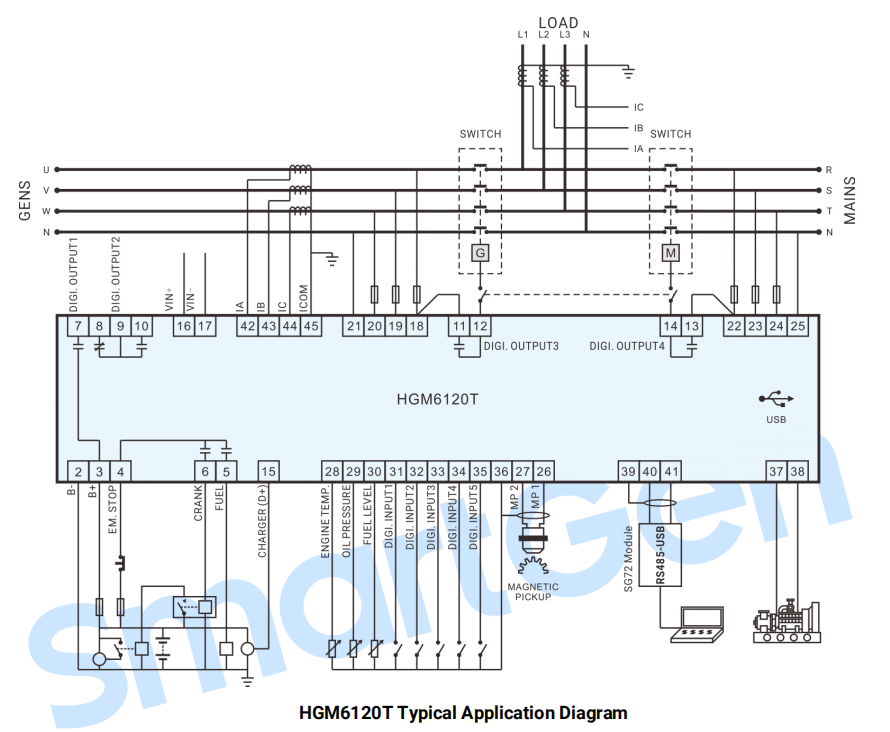

HGM8140Z controller is used for single unit automation, which can control genset to start/stop by detecting DC input voltages or remote start signals.

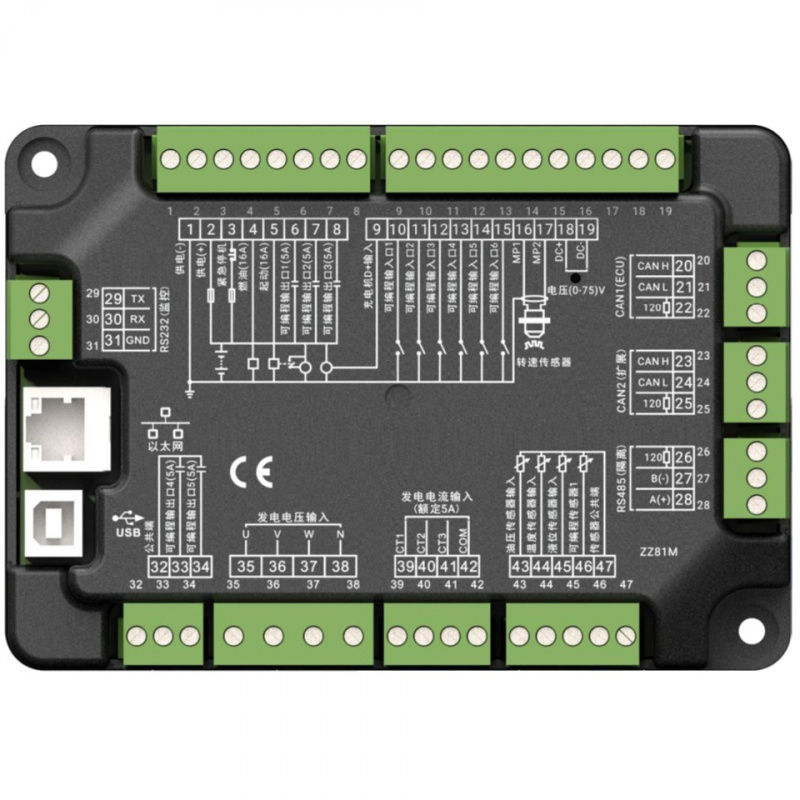

HGM8140Z controller contains two modules: HGM8140ZM (main control module) and HGM8140ZD (display module). Two modules can communicate with each other by RS232 or CAN BUS communication.

HGM8140ZM (main control module): It is used for collecting genset parameters, monitoring and protecting genset, and realizing genset auto start/stop function.

HGM8140ZD (display module): It is used for displaying genset parameters, adjusting parameters and controlling genset by the keys on the front panel of controller.

Main features are as follows:

● 132x64 LCD with backlight, selectable language interface (Chinese, English and Spanish), push-button operation;

● Hard-screen acrylic material been used to protect screen with great wear-resisting and scratch-resisting functions;

● Silicone panel and pushbuttons can be used in extreme temperature environment;

● RS485 communication interface enable “Three remote functions” (remote control, remote measuring and remote communication) according to MODBUS protocol;

● ETHERNET communication port can achieve multi-monitoring modes;

● Equipped with CAN BUS port and can communicate with J1939 genset. Not only can monitor frequently-used data (such as water temperature, oil pressure, speed, fuel consumption and so on) of ECU, but also control starting up, shutdown, speed raise and drop via CAN BUS port (need controller with CANBUS port);

● HGM8140ZM can connect with HGM8140ZD display module via RS232 or CANBUS port, which is convenient to use in special occasions. HGM8140ZD can be set as RS232 port display module or CAN port display module via front panel keys operation. HGM8140ZD module also be set as enabled/disabled control, if it is able to control, HGM8140ZM can be controlled by HGM8140ZD, otherwise, remote control function is inactive;

● Suitable for 3-phase 4-wire, 3-phase 3-wire, single phase 2-wire, and 2-phase 3-wire systems with voltage 120/240V and frequency 50Hz/60Hz;

● Collects and shows 3-phase voltage, current, power parameter and frequency of generator;

● Generator

● Line voltage (Uab, Ubc, and Uca)

● Phase voltage (Ua, Ub, and Uc)

● Frequency Hz

● Phase sequence

●Load

●Current IA, IB, IC

●Each phase and total active power kW Load output percentage %

●Reactive power kvar Apparent power kVA

●Power factor PF Accumulate total generator power kWh

●For generator, controller has over and under voltage, over and under frequency, over current and over power detection functions;

●Precision measure and display parameters about engine;

●Temp. (WT) °C/°F

●Oil Pressure (OP) kPa/psi/bar

●Fuel Level (FL) % Fuel Quantity Left L(unit)

●Speed (RPM) r/min

●Voltage of Battery V

●Voltage of Charger V

●Hour count accumulation

●Start times accumulation

●Protection: automatic start/stop of the genset, ATS (Auto Transfer Switch) control with perfect fault indication and protection function;

●With ETS (energize to stop), idle control, pre-heat control and raise/drop speed control functions, which are all relay outputs;

●Parameter setting: parameters can be modified and stored in internal FLASH memory and cannot be lost even in case of power outage; most of them can be adjusted using front panel of the controller and also can be modified using PC via USB or RS485 port;

●Multiple temperature, pressure, oil level sensor can be used and defined directly;

●Multiple crank disconnect conditions (speed sensor, oil pressure, generator frequency) are optional;

●All display interfaces can be adjusted;

●With emergency start function, which can be achieved by input port (Emergency Start) or press manual button and start button simultaneously on the panel. This function is used in the status of very low temperature in the winter and start

genset manually in a very long time;

●With battle mode, all shutdown alarms except for emergency shutdown and over speed warning alarms are inhibited;

●With flywheel tooth number automatic recognition function;

●Widely power supply range DC(8~35)V, suitable to different starting battery voltage environment;

●All parameters used digital adjustment, instead of conventional analog modulation with normal potentiometer, more reliable and stable;

●With maintenance function. Types (date and running time) can be optional and actions (warning, shutdown or trip and stop) can be set when maintenance time out;

●Event log function. Maximum 99 event logs can be memorized;

●Data analysis function. 5 circular logs and genset detailed data in one minute before shutdown alarms;

●Real-time clock, scheduled start & stop generator (can be set as start genset once a day/week/month whether with load or not);

●Waterproof security level IP65 due to rubber seal installed between the controller enclosure and panel fascia;

●Modular design, anti-flaming ABS plastic enclosure, pluggable connection terminals and embedded installation way; compact structure with easy mounting.