New product & New Funciton & New Highlight

New product & New Funciton & New Highlight

New Features N0.1

Line Voltage (L-L) Power Supply

At present, the power supply of conventional control modules in the industry are generally AC phase voltage (L-N) power supply, or phase voltage + DC power supply. In some three-phase and three-wire applications, if there is no DC power supply, it is very troublesome to solve the power supply problem of the control module. It is necessary to separately add DC switching power supply and switch two-way L-L through relay to supply the AC input end of the switching power supply. Not only increasing the cost and occupying the cabinet space, but also reducing the reliability of the system. So what shall we do?

Don't worry, it's no big deal with HAT820! HAT820 control module power supply adds AC line voltage (L-L) power supply function, providing the perfect solution for three-phase and three-line applications such as power plants and chemical plants. HAT820 can provide customers with three power supply modes: 1. DC (DC8-35v); .2. AC phase voltage L-N; 3. AC line voltage L-L (90-576v).

Load End Voltage Detection

HAT820 control module increases the voltage of the load (L-N) detection, the control module not only detects the closing state of the switch, but also detects the load end voltage. If after the success of the closing or loading into the voltage of the lines in the process of normal load voltage, the control module will display load no voltage alarm, remind users to check the switch failure. The user can choose to enable or disable this feature.

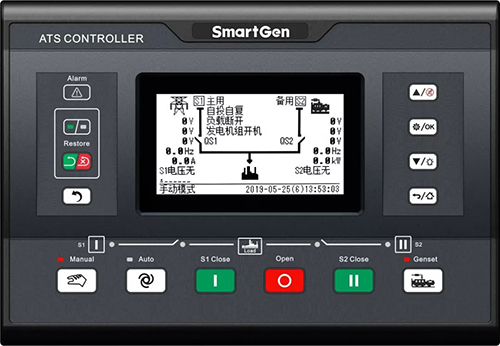

Key Switch Self-restoring & Non-self-restoring

At present, HAT600 and HAT700 need to enter the control module settings to switch between non-self-restoring while the front panel of HAT820 control module adds the keys and instructions of self-restoring and non-self-restoring , which can be directly switched between self-restoring and non-self-restoring, making it easy and fast for users to operate.

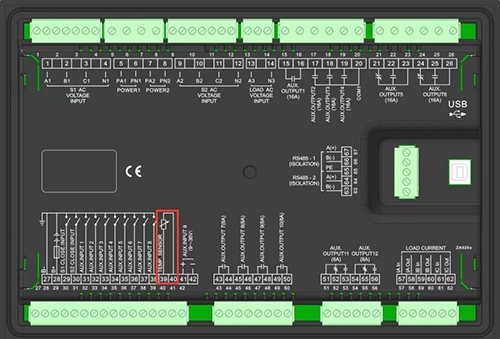

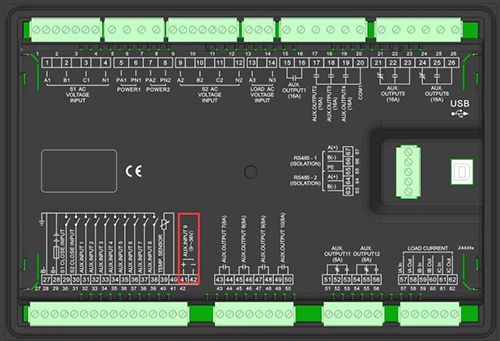

Programmable Input Port Active Input

The programmable input port of HAT820 has been added with one active input, and the programmable input port 9 is (DC 9-36v) active input, which can be used for fire control cutting (forced breaking) input and other functions.

Black Box Recording

Log events of the state information, voltage, frequency, current and other parameters before and after the event. Helping users to analyze data and determine faults.

The black box can record up to five events. Each event records status information for a total of 60 seconds before and after the event, recording once per second. When the number of records exceeds 5, the new record covers the original one. The first record is the latest one, users can check each record by the confirm key, and check the specific data status of 60 records in each record by the up and down keys.

Temperature Detection

The HAT820 can be externally connected with resistance type temperature sensor (PT100) to detect the temperature inside the cabinet. The draught fan can be started and stopped according to the setting temperature to prevent the temperature inside the cabinet from being too high.