SmartGen HEM4100EX Engine Exhaust Control Module

* All prices on this website are retail in USD on EXW incoterms

Technical Parameters:

Display LCD(132*64)

Operation Panel Silicon Rubber

Language Chinese & English

Digital Input 5

Digital Output 5

Monitor Interface RS485

Programmable Interface USB/RS485

RTC & Event Log ●

DC Supply DC(8-35)V

Case Dimensions(mm) 135*110*46(mm)

Panel Cutout(mm) 116*90(mm)

Operating Temp. (-25~+70)℃

Product Overview:

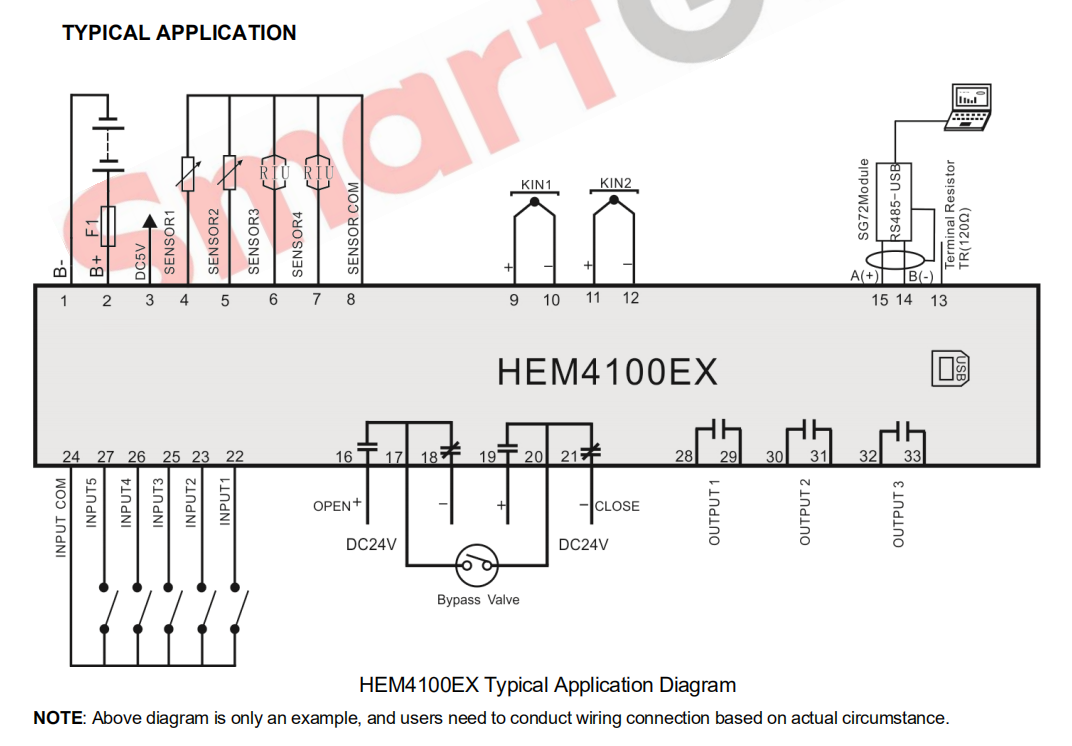

HEM4100EX Engine Exhaust Controller is a kind of engine exhaust control module which integrates programmable function, automatic measurement, and digital communication. It also integrates digitization, intellectualization, and networking, and measuring and control process gets automated, which reduces human operation mistakes. It is the ideal product of handling engine exhaust. It applies LCD graphic display, which can display Chinese, English two languages. It is easy to operate, and reliable to run.

HEM4100EX Engine Exhaust Controller is composed by microprocessor in the core, which can precisely detect inlet temperature, outlet temperature, back pressure, and make accurate judgment for the occurred abnormal temperature and pressure and control bypass valve close/open. It realizes threshold setting function for many parameters. A majority of parameters can be adjusted from the controller front panel. All parameters can be adjusted via USB or RS485 port by using PC. It has compact structure, advanced circuit, simple wiring, and high reliability and can be widely applied in electric and automatic control system of engine exhaust handling.

PERFORMANCE AND CHARACTERISTICS

132x64 LCD with backlight, bilingual interface display (including English and Chinese languages) and tuch-button operation;

Precisely collect all kinds of parameters in the process of handling engine exhaust;

Inlet Temperature Unit: °C/°F

Outlet Temperature Unit: °C/°F

Back Pressure Unit: kPa/psi/bar

Running Time (Current) Max. 9999 hours

Total Running Time Max. 65535 hours

Total Bypass Open Numbers Max. 65535 times

Control and protection function: realizes back pressure high alarm, indicates purification carrier, and opens bypass valve pressure reduction function;

Bypass value open, bypass value close, alarm output, inlet temperature high output, inlet temperature low output, outlet temperature high output functions, all of which are relay outputs;

Auto/Manual status transfer is equipped, in manual mode, operator can hand control close or open bypass valve;

Parameter setting function: allows users to change or set the parameters, which won't get lost in case of power outage. A majority of parameters can be adjusted from controller front panel, and all parameters can be adjusted via USB or RS485 ports by using PC;

Custom sensor curve, resistor, voltage or current type sensors can be connected for configurable 3 and configurable 4;

Bypass valve open or close output can be set to pulse or continuous output;

Real Time Close display, historical record function, which can record 200 data circularly;

One way RS485 isolated communication port, which has remote control, remote communication, remote measurement, remote adjusting functions; bypass valve open or close can be remotely controlled;

Silicone gasket is designed between enclosure and control window; Waterproof performance reaches IP65;

Controller applies metal clip fixing;

Modular structure design, pluggable connection terminal, build-in installation method with compact structure and convenient mounting.